ethylene absorber 3A molecular sieve ethanol distillation

Basic Info

Model No.: 3a

Product Description

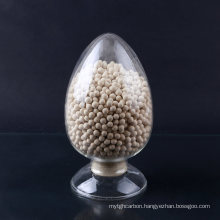

ethylene absorber 3A Molecular Sieve ethanol distillation

Description

3a Molecular sieves, also called the zeolite 3a molecular sieves. It can adsorb any molecular diameter less than 3 Å

Mainly used in deep desiccation of cracked petroleum gases, such as ethylene, propylene, butadiene, acetylene and natural gas, and of polar liquid, such as ethanol, LPG and solvent.

Speciafication of zeolite ethylene absorber :

Item | Unit | Technical data | |

Shape |

| Sphere | |

Diameter | mm | 1.7-2.5 | 3.0-5.0 |

Size ratio up to grade | % | ≥96 | ≥96 |

Bulk density | g/ml | ≥0.66 | ≥0.66 |

Attrition loss | % | ≤0.20 | ≤0.20 |

Crushing strength | N | ≥30/piece | ≥60/piece |

Static water adsorption | % | ≥21.5 | ≥21.5 |

Ethylene adsorption | ‰ | ≤3.0 | ≤3.0 |

Package Moisture | % | ≤1.5 | ≤1.5 |

The specification could be adjusted as customer's requirements

Photos

zeolite ethylene absorber applications as follows

- Drying of unsaturated hydrocarbons (e.g. ethylene, propylene, butadien)

- Cracked Gas Drying

- Drying of natural gas

- Drying of highly polar compounds, such as methanol and ethanol

- Drying of liquid alcohol

- Static,( 55314639,non-regenerative) dehydration of insulating glass units, whether air filled or gas-filled.

- Drying of refrigerants

Regeneration of zeolite ethylene absorber :

To achieve good operating performance and long life as much as possible, after a certain period of time use must be regenerated .

After correct molecular sieve regeneration , make it get the low attenuation of mechanical properties and adsorption

There are two basic approaches:

- Temperature variation .

Generally used in the preheating gas heating, purge molecular sieve to about 200 º C, and stripping down the adsorbate .

- Variable pressure .

Usually used in the gas phase adsorption process.Maintain a constant temperature adsorbent and by reducing pressure and backing purge inert gas , to remove the adsorbate.

The packaging for zeolite ethylene absorber :

- How about the sample?

- we can provide offer free samples and freight charges is collected

- what is the delivery time

- it will take about 7-15 days after received deposit

- could you give me a discount?

- Yes, we can have a negotiatio

- what is shipping way?

- By sea,by air,by courier.international train

- what is the type of your company?

- We are manufacture and trading company.

If you have any quetstions,Please contact us

1.Free sample

2.Catalogues and photos of this product.

3.The packing can be made according to customers’ requirments.

4.On time delivery

5.If there are any quality problems within one year we will handle in time .

| Name: | Gella Gao |

| Tel: | 0086-15638283291 |

| Skype: | gyhongchang01 |

| Whatsapp/wechat | 0086-15638283291 |

Product Categories : Molecular Sieve

Premium Related Products